In the intricate world of automotive maintenance, the choice between gear oil vs engine oil is a critical decision that directly impacts the performance and durability of your vehicle.

As the heartbeat of your automobile, the engine and its internal components rely on the right lubrication to function smoothly, while the gearbox demands a specialized solution to navigate the complexities of power transmission.

This article delves into the nuanced realm of gear oil versus engine oil, unraveling the distinctions between these lubricants, their unique roles, and the essential considerations for making informed decisions that resonate with the specific needs of your vehicle.

Whether you’re a seasoned motor enthusiast or a novice in the automotive realm, understanding the differences between these two essential lubricants is paramount for the overall health and longevity of your cherished ride.

Table of Contents

gear oil vs engine oil

In this comparison, we’ll explore the characteristics, functions, and applications of gear oil and engine oil, aiding you in making informed decisions for the optimal care of your beloved vehicle.

Composition and Primary Functions

Composition and Primary Functions: Decoding the Core Elements of Gear Oil and Engine Oil

Understanding the intricate makeup of gear oil vs engine oil is fundamental to appreciating how these lubricants contribute to the optimal functioning of different components within a vehicle.

In this segment, we delve into the composition and primary functions of gear oil and engine oil, shedding light on the specialized nature of these essential fluids.

Engine Oil

Speaking about gear oil vs engine oil, we will mention here the Composition of engine oil.

Composition:

Engine oil is a sophisticated blend of base oils and a diverse array of additives, each serving a specific purpose.

The base oils can be mineral, synthetic, or a combination of both, providing the primary fluidic medium for the lubricant.

Primary Functions:

Friction Reduction: Engine oil forms a protective layer between moving components, reducing friction and minimizing wear on critical parts like pistons, camshafts, and crankshafts.

Heat Dissipation: As the engine operates, it generates substantial heat. Engine oil absorbs and dissipates this heat, preventing overheating and ensuring a stable operating temperature.

Cleaning and Dispersing: Detergent and dispersant additives in engine oil help cleanse the engine by suspending and dispersing contaminants, preventing sludge buildup and maintaining cleanliness.

Corrosion Protection: Engine oil contains corrosion inhibitors that shield metal surfaces from oxidation and corrosion, prolonging the life of engine components.

Seal Conditioning: Specialized additives maintain the flexibility of seals, gaskets, and O-rings, preventing leaks and ensuring a proper seal for combustion chambers.

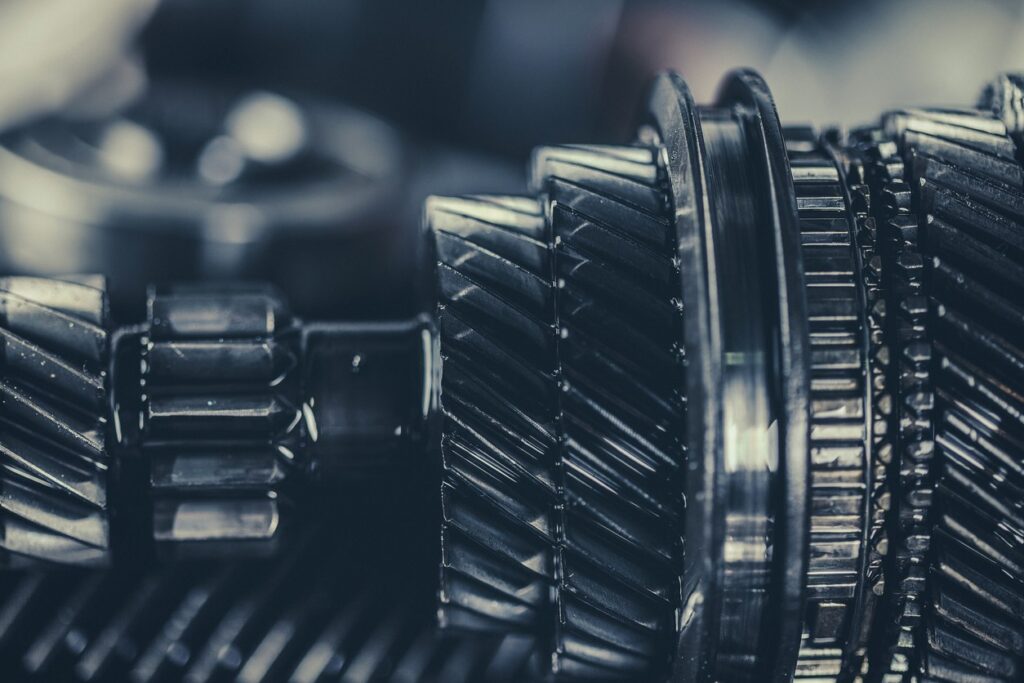

Gear Oil

Composition:

Gear oil, like engine oil, is composed of base oils, but it is formulated with a higher viscosity to withstand the intense pressures and shear forces within gearboxes.

Additionally, gear oil includes additives tailored to enhance extreme pressure (EP) properties.

Primary Functions:

Lubrication of Gears and Bearings: The primary role of gear oil is to lubricate gears and bearings in transmissions, differentials, and other gear mechanisms. The higher viscosity ensures effective lubrication under heavy loads.

Extreme Pressure (EP) Protection: Additives in gear oil form a protective layer on gear surfaces, preventing metal-to-metal contact under extreme pressures. This is crucial for minimizing wear and extending the life of gears.

Temperature Stability: Gear oil is designed to operate effectively at high temperatures, providing stable lubrication even in the demanding conditions of gear systems.

Resistance to Foaming: Additives in gear oil prevent foaming, ensuring consistent lubrication and avoiding air entrainment, which can compromise performance.

In essence, while both engine oil and gear oil share the fundamental purpose of lubrication, their specialized compositions and functions align with the unique demands of engines and gear systems, respectively. Selecting the right lubricant for each application is key to optimizing the performance and longevity of your vehicle’s crucial components.

Read more: What gearbox oil do i need?

Viscosity and Temperature Range

Viscosity and Temperature Range: Navigating the Fluid Dynamics of gear oil vs engine oil.

The viscosity and temperature range of lubricants are critical parameters that dictate their performance in various automotive systems. In this exploration, we unravel the fluid dynamics of gear oil and engine oil, examining how viscosity and temperature considerations play a pivotal role in their effectiveness within the dynamic environments of engines and gearboxes.

Engine Oil

Viscosity:

Engine oil comes in various viscosity grades, denoted by numbers such as 5W-30 or 10W-40.

The “W” stands for winter, indicating the oil’s flow characteristics in cold temperatures.

The first number represents the oil’s viscosity during cold starts, while the second number signifies its viscosity at operating temperatures.

Lower viscosity allows for easier flow during start-up, ensuring rapid lubrication of critical engine components.

Temperature Range:

Engine oil is engineered to operate within a broad temperature range, from sub-zero conditions during cold starts to the elevated temperatures generated within a running engine.

The right viscosity at both low and high temperatures is crucial for maintaining optimal lubrication under diverse operating conditions.

Gear Oil

Viscosity:

Gear oil typically has a higher viscosity compared to engine oil.

This thicker consistency is essential for withstanding the extreme pressures and shear forces experienced within gearboxes and transmissions.

The higher viscosity ensures that the oil maintains a sufficient film thickness, preventing metal-to-metal contact and reducing wear on gears and bearings.

Temperature Range:

Gear oil is formulated to endure the demanding temperature conditions prevalent in gear systems.

It must remain effective at high temperatures generated during heavy-duty operations.

The temperature stability of gear oil ensures that it continues to provide reliable lubrication even in the heat generated by gears meshing under substantial loads.

Read more: lithium grease vs white lithium grease

Additives and Specialized Formulations

Additives and Specialized Formulations: Enhancing the Performance and Protection of gear oil vs engine oil.

Behind the scenes of every lubricant’s composition lies a carefully crafted blend of additives, each serving a specific purpose to optimize performance and safeguard vital components. In this exploration, we delve into the realm of additives and specialized formulations, unraveling the intricacies that distinguish gear oil and engine oil in their mission to protect and enhance the efficiency of automotive systems.

gear oil vs engine oil (Engine Oil)

Additives:

Detergents and Dispersants: Engine oil contains detergents that help clean and disperse deposits, preventing the formation of sludge and varnish in the engine. Dispersants ensure that contaminants remain in suspension, allowing them to be filtered out by the oil filter.

Anti-Wear Agents: These additives form a protective layer on critical engine components, such as camshafts and crankshafts, reducing friction and minimizing wear during operation.

Antioxidants: To combat oxidation, engine oil incorporates antioxidants that inhibit the breakdown of the oil molecules, preventing the formation of harmful by-products that can compromise the lubricant’s effectiveness.

Viscosity Modifiers: Engine oil may include viscosity modifiers to ensure consistent viscosity across a range of temperatures.

These modifiers help maintain the oil’s performance in varying operating conditions.

gear oil vs engine oil (Gear Oil)

Additives:

Extreme Pressure (EP) Additives: Given the high-pressure environment within gear systems, gear oil contains EP additives that form a protective film on gear surfaces, preventing metal-to-metal contact and minimizing wear under heavy loads.

Anti-Wear and Anti-Scuff Agents: These additives enhance the gear oil’s ability to withstand extreme pressures, reducing wear on gears and bearings and preventing scuffing under heavy-duty conditions.

Foam Inhibitors: Gear oil formulations incorporate foam inhibitors to prevent the formation of foam, ensuring consistent lubrication and minimizing the risk of air entrainment in the gearbox.

Rust and Corrosion Inhibitors: To protect gears and bearings from corrosion, gear oil includes additives that create a barrier against moisture and oxidation, extending the life of critical components.

Here, we have provided you with some information about gear oil vs engine oil Through the website jrlubricants.