In the world of machinery and mechanical engineering, the choice between oil and

grease as lubricants is a critical decision that can significantly impact performance and

longevity. Understanding the differences, types, manufacturing processes, and best

applications for these lubricants is essential for optimal equipment maintenance. In this

comprehensive guide, we will delve into the nuances of oil vs. grease, explore the types

of grease available, uncover the grease lubricant manufacturing process, and highlight

the best hand tool lubricant for various applications.

Oil vs. Grease: Exploring the Fundamental Differences

The debate between oil and grease as lubricants has been ongoing for decades, with

each option offering unique advantages and applications.

Oil:

Oil is a fluid lubricant that flows easily, providing excellent coverage and distribution.

It is ideal for situations where precise application and rapid distribution are necessary.

Oils are commonly used in engines, hydraulic systems, and precision machinery.

Grease:

Grease is a semi-solid lubricant composed of a base oil thickened with a soap, such as

lithium or calcium.

Its semi-solid nature allows it to adhere well to surfaces, making it ideal for applications

where staying power and protection against contaminants are crucial.

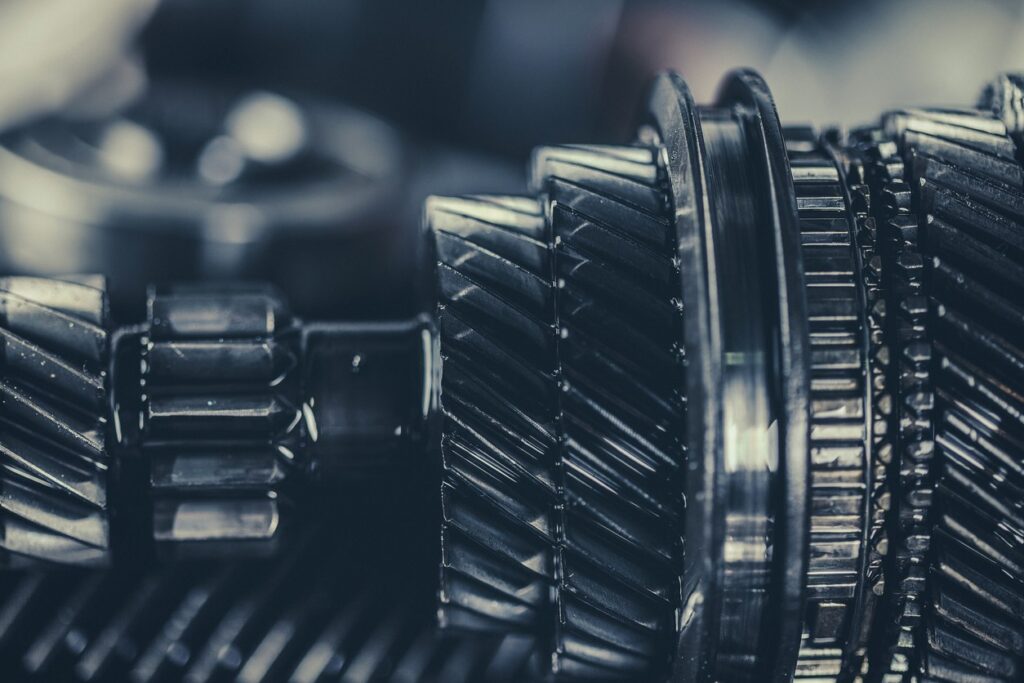

Grease is often used in bearings, gears, and heavy-duty machinery.

Types of Grease: From Lithium to Copper

Grease comes in various formulations, each tailored to specific needs and applications.

Let’s explore some common types:

Grasso AL Litio Complesso:

Grasso AL Litio Complesso falls under the category of lithium complex greases.

It is known for its exceptional performance under high temperatures and heavy loads.

This type of grease is commonly used in industrial machinery and automotive

applications.

Grasso al Rame (Copper Grease):

Copper grease is used for its anti-seize properties, particularly in automotive

applications.

It helps prevent bolts and fasteners from seizing due to heat and corrosion.

Grasso al Litio Bianco (White Lithium Grease):

White lithium grease is known for its water resistance, making it ideal for marine

applications.

It is commonly used in boat trailers, winches, and other marine equipment.

Grasso Bianco Corpo (Body White Grease):

Body white grease is a general-purpose lubricant with good stability and anti-wear

properties.

It is suitable for a wide range of applications, including hinges, latches, and sliding

mechanisms.

Grease Lubricant Manufacturing Process

The manufacturing process of grease is a precise and controlled operation that involves

several key steps:

- Base Oil Selection: The first step is selecting the base oil, which can be mineral oil,

synthetic oil, or a blend of oils. - Thickener Addition: The selected base oil is then mixed with a thickener, such as

lithium hydroxide, to create the semi-solid consistency of grease. - Additive Incorporation: Various additives, such as anti-wear agents, corrosion

inhibitors, and antioxidants, are added to enhance the grease’s performance and

properties. - Homogenization: The mixture is then homogenized to ensure a uniform distribution of

the thickener and additives throughout the grease. - Packaging: The final step involves packaging the grease into containers or cartridges

for distribution and use.

Greece Oil Discovery and Oil Fields

Greece, with its rich history and culture, has also made significant strides in the oil

industry. The discovery of oil fields in Greece has contributed to the nation’s economy

and energy independence. Some notable oil fields in Greece include:

Prinos Oil Field: Located in the northern Aegean Sea, the Prinos Oil Field is one of

Greece’s largest producing oil fields.

South Kavala Oil Field: Situated in the northern part of Greece, this oil field has

contributed to Greece’s oil production since its discovery.

Best Hand Tool Lubricant: Grasso AL Litio Complesso

When it comes to hand tool lubricants, Grasso AL Litio Complesso stands out as an

excellent choice. Its lithium complex formulation offers several advantages:

High-Temperature Stability: Ideal for hand tools that operate under high heat

conditions.

Excellent Load-Carrying Capacity: Provides optimal lubrication for heavy-duty tools

and equipment.

Corrosion Protection: Guards against rust and corrosion, extending the lifespan of

tools.

Water Resistance: Maintains effectiveness even in wet or humid environments.

Graphite Oil and Lubricant Definition

Graphite oil is a dry lubricant that consists of fine graphite particles suspended in a

liquid carrier. It is commonly used in locks and mechanisms where traditional liquid

lubricants may attract dust and debris.

Grease Prices and Grease Definition

Grease prices can vary based on factors such as the type of thickener used, the quality of

base oils, and market demand. Generally, lithium-based greases tend to be more

expensive due to their superior performance and longevity.

Grease, in simple terms, is a semi-solid lubricant composed of a base oil thickened with

additives to create a viscous substance. Its main purpose is to reduce friction and wear

between moving parts in machinery and equipment.