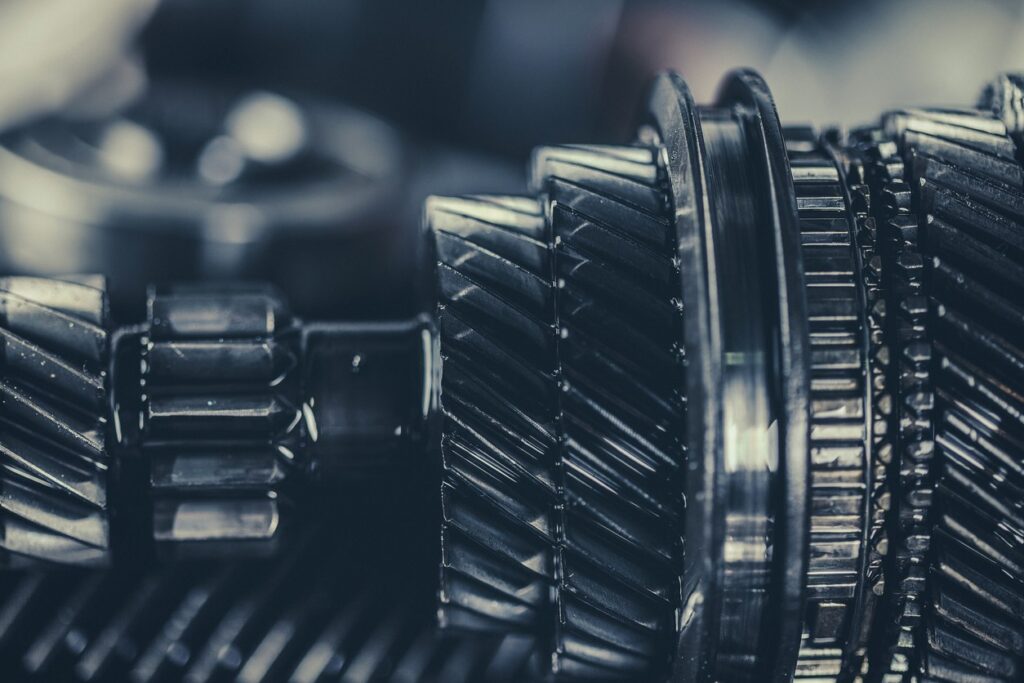

In heavy-duty applications, the right lubricant is not just a requirement; it’s a backbone for reliability and efficiency. High-quality lubricants play a crucial role in minimizing wear and tear, ensuring machinery operates smoothly under extreme conditions. JR UNYSIN GRASSO – 460 emerges as a beacon in this realm, specifically engineered for environments that challenge the endurance of anti-friction and plain bearings. Tailored for sectors like steel works, quarries, and heavy machinery, it promises not just lubrication but a safeguard against the rigors of high load and temperature.

High-Performance Lithium Complex Grease: JR UNYSIN GRASSO – 460

JR UNYSIN GRASSO – 460 stands out as a superior heavy-duty Lithium Complex grease, designed to cater to the rigorous demands of various industries. Its formulation makes it ideal for both anti-friction and plain bearings, ensuring reliable performance in diverse sectors such as steel production, quarry operations, and heavy machinery utilization. This premium grease is tailored to provide optimal lubrication, thereby enhancing the efficiency and longevity of equipment subjected to high stress and temperature conditions.

Advanced Technology in JR UNYSIN GRASSO – 460: Enhancing Performance and Efficiency

JR UNYSIN GRASSO – 460 incorporates advanced technology with its blend of extreme pressure, anti-wear, antioxidant, and corrosion-inhibiting additives. These features synergize to ensure exceptional performance by significantly enhancing the grease’s ability to withstand heavy loads and severe service conditions. The formulation not only protects machinery components from wear and corrosion but also extends lubrication intervals, reducing downtime and maintenance costs, thus offering a reliable solution for industries seeking to optimize operational efficiency and equipment longevity.

Versatile Industrial Applications of JR UNYSIN GRASSO – 460

JR UNYSIN GRASSO – 460 is exceptionally well-suited for a wide range of industrial applications. It excels in environments such as steel works, where machinery is subjected to extreme conditions; quarries, where dust and heavy loads challenge equipment longevity; and in the operations of heavy plant machinery that demands robust lubrication performance. Additionally, its benefits extend to dockside, offshore, and fishing industries, where equipment faces the corrosive nature of marine environments. This versatility underscores its effectiveness across diverse sectors requiring high-performance lubrication solutions.

- Elevate Your Machinery’s Performance with JR Grasso Ordinario SOD – MP2: The Premium Multi-Purpose Sodium Grease

- Unleashing the Power of JR Olio Motore 20W50: The Ultimate Engine Protector

- Unleash Efficiency and Reliability with JR Olio Lub Per Catene: The Ultimate Chain Lubricant

- Unleashing Performance with JR Grasso Ad Alta Velocità: The Ultimate Guide

- Maximizing Performance with JR Lubrificante Adesivo-2500: A Comprehensive Guide

Exceptional Performance in Extreme Conditions: JR UNYSIN GRASSO – 460

JR UNYSIN GRASSO – 460 is designed to excel under extreme conditions, maintaining its protective qualities under high loads and high temperatures. This reliability and durability ensure equipment operates smoothly, reducing wear and extending service life, even in the most demanding environments.

How should JR UNYSIN GRASSO – 460 be applied to machinery?

pply JR UNYSIN GRASSO – 460 using standard grease guns or automatic lubrication systems, ensuring thorough coverage on the intended surfaces. Always clean the application area before use to avoid contamination.

What safety measures should be observed when using JR UNYSIN GRASSO – 460?

Wear protective gloves and eyewear to prevent skin and eye contact. Use in well-ventilated areas and follow the manufacturer’s safety datasheet recommendations.

How is JR UNYSIN GRASSO – 460 stored to maintain its efficacy?

Store in a cool, dry place away from direct sunlight and extreme temperatures. Keep the container tightly closed when not in use to maintain the grease’s properties.

Can JR UNYSIN GRASSO – 460 be used in food-grade applications?

JR UNYSIN GRASSO – 460 is designed for industrial use. Verify if it meets the specific certifications required for food-grade applications before use in such environments.

What are the temperature limits for the effective use of JR UNYSIN GRASSO – 460?

Consult the product specifications for the effective temperature range. JR UNYSIN GRASSO – 460 is formulated to perform under high temperature conditions, but specific limits should be adhered to for optimal performance.